Rupture Discs

Bursting discs are, in addition to safety valves, the most commonly used pressure protection devices in industrial installations. They protect vessels and pipelines against deformation and other damage. The main goal is to provide optimal protection while minimizing system downtime.

Forward acting rupture disc

The FLCO rupture disc from OsecoElfab is easy to install and not torque sensitive. The rupture disc can be used between standard 150# ANSI RF flanges.

Flat Low Pressure Composite (FLCO)

The FLCO rupture disc from OsecoElfab is easy to install and not torque sensitive.

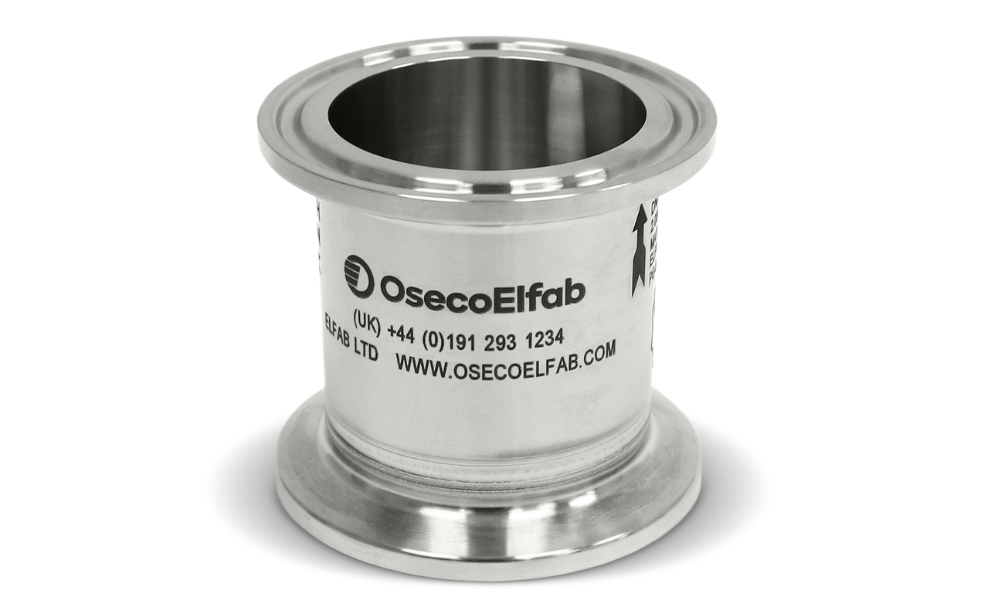

Opti-Gard Ferrule

The Opti-Gard Ferrule is specifically designed for the food and beverage, biotechnology and biopharmaceutical industries.

Universal Arma-Gard

As a non-torque sensitive graphite rupture disc, Universal Arma-Gard has a retainerless design for easy installation between industry standard flanges (PN, ANSI, BS).

Low pressure disc

Ultra low pressure rupture disc for gas and vapour applications.

Tank-Safe

Reliable protection for rail cars and intermodal containers.

Transportation disc

This type of rupture disc (HCL-RC) is commonly used in rubber lined railway tank cars. And is suitable for use in Hydrochloric Acid (Hydrochloric Acid) applications.

Reverse acting rupture disc

OsecoElfab’s PRO+KRGL is a reverse acting rupture disc designed and manufactured for high cycling performance and demanding applications.

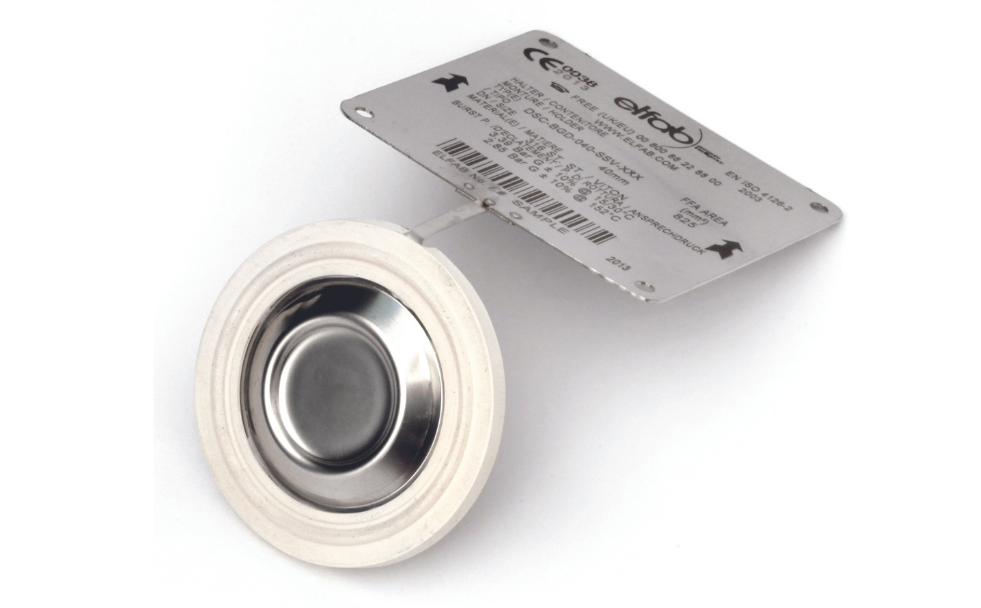

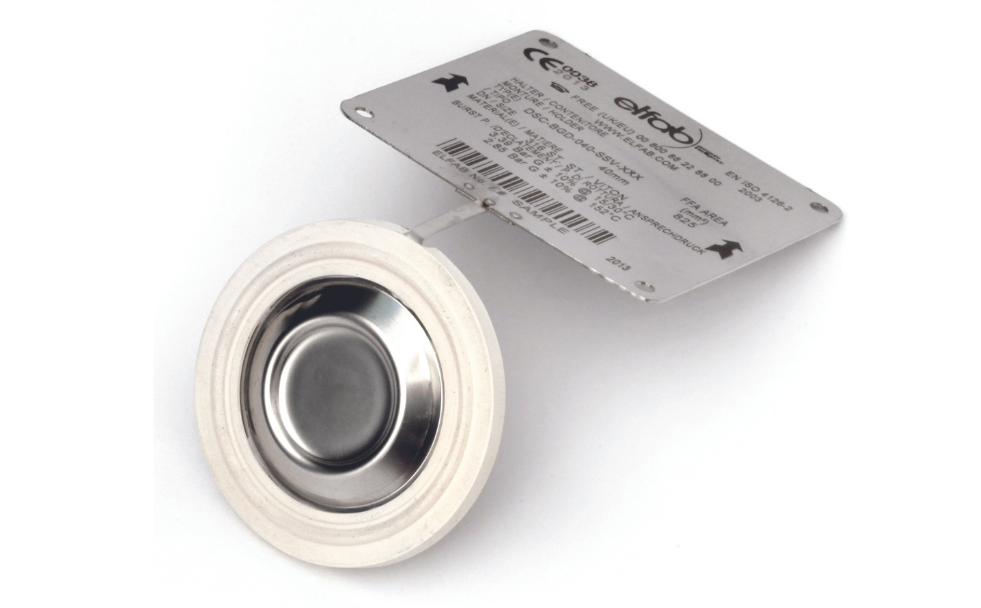

Pure-Gard

Pure-Gard is a sanitary welded rupture disc cartridge designed for the stringent conditions and requirements found in bioprocessing facilities.

Bio-Gard

Bio-Gard offers full-bore relief for reliable overpressure protection in aseptic and hygienic plants.

Bio-Gard

Bio-Gard biedt volledige doorlaat voor betrouwbare overdrukbeveiliging in aseptische en hygiënische installaties.

Flat Composite Bursting Disc

An economic solution for very low pressure applications

Oseco Safety Cartridge

Combines the traditional three components of a rupture disc system into one hermetically sealed component

Oseco veiligheidscartridge

Combineert de traditionele drie componenten van een breekplaatsysteem in één hermetisch afgesloten onderdeel

Opti-Gard SoLo

Accurate bursting in low pressure applications

Bursting discs are safety devices with a defined rupture point that respond to a specific pressure and are used for pressure relief in a wide variety of applications. They are used as protection against overpressure or vacuum in a process, to protect people, the environment and the machine. Originally a very simple solution, rupture discs have evolved enormously in response to increasing industry demands, such as varying pressures or higher process temperatures, and the increasing technologicalization of processes in recent years. The biggest advantage over electronic, pneumatic or spring-loaded safety systems is the fail-safe performance of rupture discs – making them the most economical and most important safety feature in industrial enterprises. High reliability is important to prevent unnecessary system downtime. How safe a rupture disc is, however, strongly depends on the workmanship and the material used.

About Rupture discs

As you can see above, there are various types of rupture discs available, each with its own specific properties.

Two of the most common discs types are:

"Reserve acting" rupture discs

The rupture disc dome faces the process and allows for very high working pressures (see also: important technical information about rupture discs) and a very high working pressure ratio.

"Forward acting" rupture discs

The rupture disc dome faces away from the process.

OsecoElfab Rupture discs

OsecoElfab is one of the world’s largest market leaders in the design and manufacture of rupture discs, rupture disc holders, rupture disc detection and explosion panels, also known as rupture discs, burst discs, rupture disc holder, burst indicators, explosion panels.

As an A-brand manufacturer, OsecoElfab stands for the highest quality and safety, driven by its customers’ demand for ever better performance, customer-specific solutions and very high reliability

The Delta Engineering rupture disc team, partner of Oseco Elfab, has experience in rupture discs since 1997 and specializes in both overpressure protection and negative pressure protection. You can contact us 24/7 for all your questions regarding pressure protection.